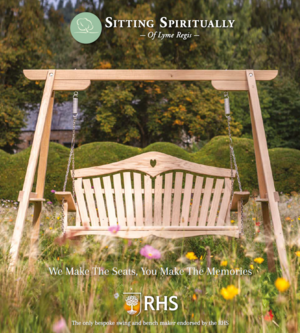

- Swing Seats

Delivery and Assembly Available

Bespoke Inscriptions

Handcrafted in Devon

- Day Beds

Delivery and Assembly Available

Bespoke Inscriptions

Handcrafted in Devon

- Rope Swings

Delivery and Assembly Available

Bespoke Inscriptions

Handcrafted in Devon

- Benches

Delivery and Assembly Available

Bespoke Inscriptions

Handcrafted in Devon

- Pergolas

Delivery and Assembly Available

Bespoke Inscriptions

Handcrafted in Devon

- About

Delivery and Assembly Available

Bespoke Inscriptions

Handcrafted in Devon

- Blog

- Contact/Visit Us

Delivery and Assembly Available

Bespoke Inscriptions

Handcrafted in Devon

The Timbers We Work With.... By James Amato

The most important part of our products is the raw material – the wood itself. Firstly, care is taken to source the wood, all of which comes under the FSC (Forest Stewardship Council). We only select the best grade wood at Sitting Spiritually, and we, as makers, are part of the quality selection process. When we receive a wood delivery, our first job is to carefully inspect the timber to ensure that we start with the best grade of material. This means we look over it for large knots, or any evidence of sapwood, splitting or shakes (shakes are a lengthwise separation along the grain, usually between the growth rings of the tree). Heartwood (the central, ‘dead’ inner part of the tree) is rejected, as again, this is more susceptible to splitting and imperfections. When we are completely happy with the wood, we can then start the process of creating the furniture. This begins by marking out the components and cutting out using the bandsaw and router. In turn these are processed and sanded, finished and perfected, ready for assembly. There is something incredibly satisfying about receiving a raw material, such as timber and processing that material into a beautiful piece of furniture. This has to be one of the most rewarding aspects of making the furniture.

Below are the three woods that we use at Sitting Spiritually. They each have unique properties and characteristics which make them suitable for various purposes, we get to ‘know’ the wood after years of working with it, and we have developed different ways of working that we find are the most harmonious with that particular material.

The Affinity Garden Swing Seat in Painted Accoya®

Accoya® long life treated wood is the timber industry benchmark for performance and sustainability. No other timber can offer this combination of stability, durability and versatility. This modified wood is sustainably sourced with FSC® certification and it has minimal environmental impact throughout its entire life. Accoya® is wood, but not as you know it. It is modified timber in which a process called acetylation, a cutting-edge patented technology, enables it to resist rot, defy the elements and stay strong for decades. Accoya®is a world-leading natural solution against huge global environmental concerns – including climate change, ecosystem destruction and finite renewable resources. All of which, could make your design a masterpiece in sustainability.

Our Affinity Garden Swing Seat in Painted Accoya® has a 25-year warranty.

The RHS Serenity Range in Cedar

Western Red Cedar is a fantastic material to work with, and our Serenity swing seat looks beautiful in this prestigious wood. Cedar fills the workshop with an incredible aroma when we are working with this material to create the swing seats. It is lightweight (also a softwood like pine) but incredibly strong, and this makes it enjoyable to work with. Of course Cedar is one of the most suited woods for outdoor-use as it is very durable, and it also naturally has some resistance to moths and other insects as well as fungal attack. It is fairly brittle and splinters easily, so great care must be taken when shaping and finishing components. A properly finished product looks exceptionally beautiful with the natural grain of the Cedar tree, and in my opinion this timber is the best looking of the timbers we use.

The Tranquillity Range in Oak

My favourite timber overall, however, has to be oak. The slow-growing Northern European oak we use means that this very dense hardwood keeps us busy! Notorious for blunting drill-bits and being extremely hard, this is counterbalanced by the exceptional longevity of this beautiful wood. There is a great thrill in finishing an oak day bed or swing seat. This is because the overall look of oak looks so harmonious. We know that this creation, already having taken years to grow, is now going to enjoy a lifetime of enjoyment in it’s new form – as a beautiful piece of outdoor furniture. Finished pieces, such as the new Knole Garden Bench, can be very heavy to manoeuvre around the workshop though! We use a kiln-dried oak for most of the products (apart from pergolas, which are made from green oak), which guarantees minimal movement of the timber when placed in its final position in a customer’s garden. Like cedar, but to a lesser degree, the dry timber can be brittle so care is again taken in the shaping of components.

Many thanks to James Amato

Posted by Siobhan on July 8th 2019